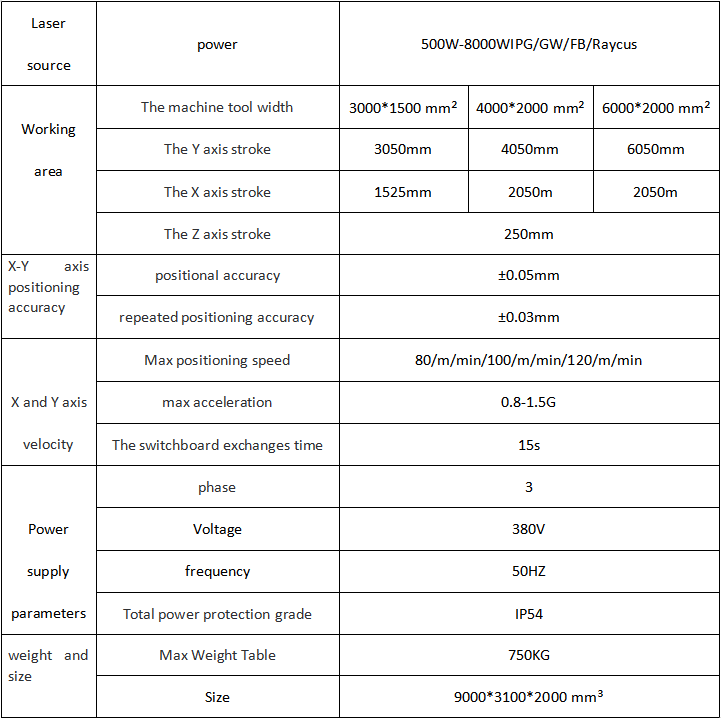

Technical Parameters:

Application:

Metal laser cutting machine is suitable for all kinds of sheet metal or pipe of high speed cutting, rail transport, shipbuilding, automobile, engineering machinery, forestry machinery, electrical manufacturing, elevator manufacturing, household appliances, food machinery, textile machinery, tools, processing, petroleum machinery, food machinery, kitchen utensils and appliances, sanitary ware, decorative advertising, laser processing services and so on all kinds of machinery manufacturing processing industry;It is mainly used in carbon steel, stainless steel, aluminum alloy, brass, copper, pickling plate, galvanized plate, silicon steel plate, electrolytic plate, titanium alloy, manganese alloy, stainless steel, carbon steel, aluminum plate, steel plate, alloy plate and other metal materials.

Work Principle:

Laser cutting uses a laser generator as a light source, and a focused high-power density laser beam irradiates the workpiece to quickly melt, vaporize, ablate or reach the ignition point of the irradiated material. At the same time, the molten material is blown away by the high-speed airflow coaxial with the beam. , So as to realize the work piece is cut apart. Because the light source is stable and reliable, it can be used for plane cutting or three-dimensional cutting. The cutting speed is fast and the edges are neat and smooth. It is widely used in metal, ceramic, and flexible circuit board material cutting.

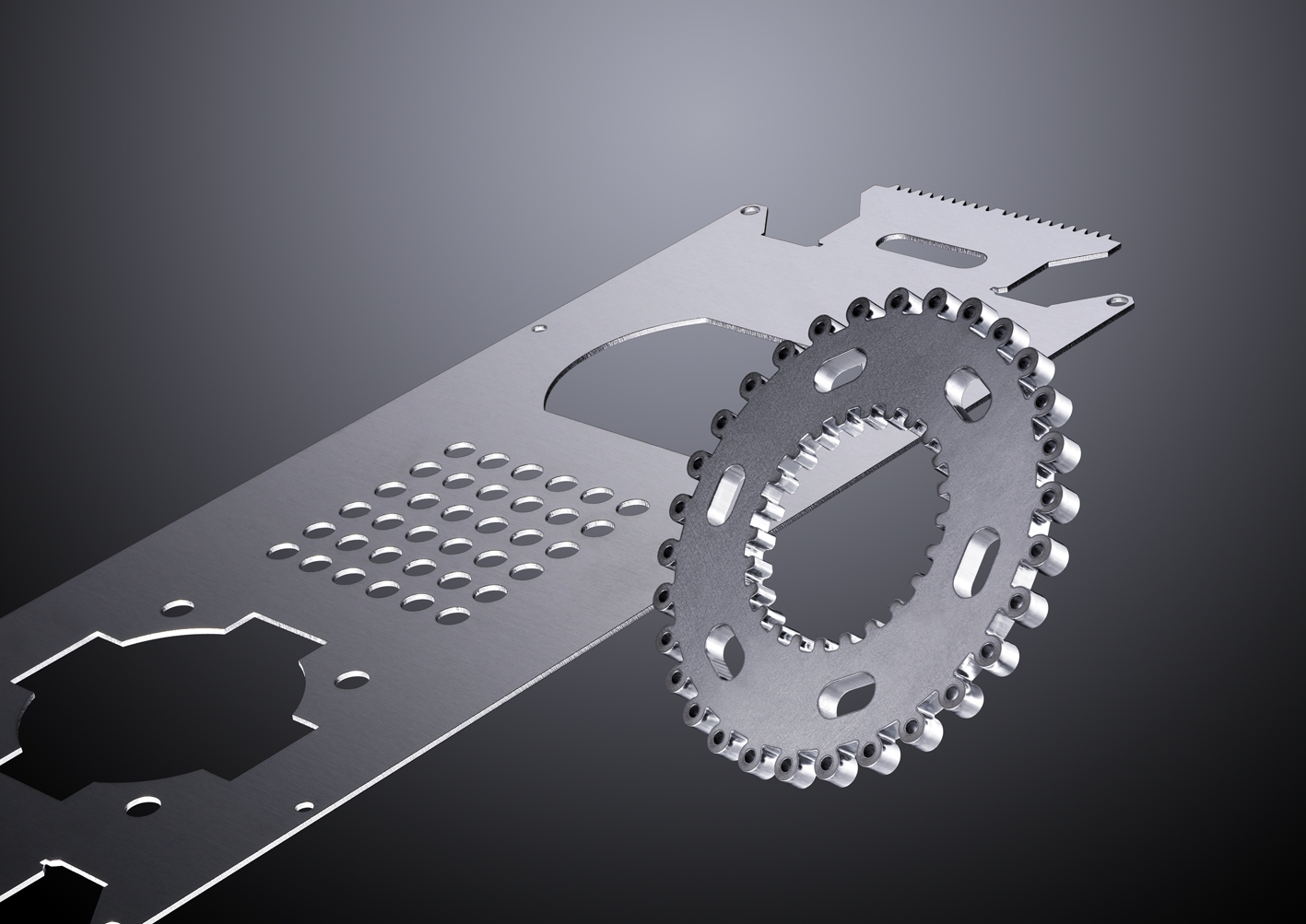

Samples:

Reviews

There are no reviews yet.